Company history

It all started on November 16, 1947 with the Decree of the Government of the USSR on the construction of the Gorky hydroelectric power station. From the same time, the settlement originated, which later became the city of Zavolzhye. To ensure the construction of construction materials, by order of GORKOVGESSTROY, a woodworking enterprise "Lesokombinat" was organized on the banks of the Volga River.

The date of foundation is December 11, 1947.

The company is included in the structure of Glavvolgovyatstroy. DOZ No. 3 becomes one of the leading suppliers of woodworking products to the Main Committee of the Supreme Council of the National Economy of the RSFSR.

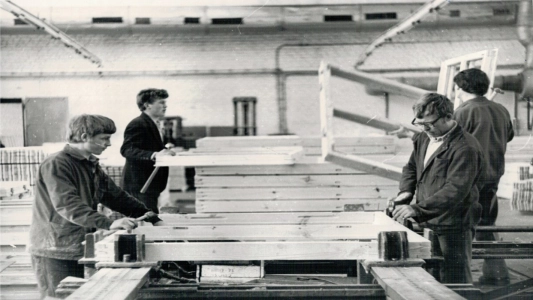

Zavolzhsky DOZ actively participated in many construction projects of that time as part of the Glavvolgovyatstroy branch association. The company was engaged in the sawing of roundwood, the production of mouldings, the production of windows and doors.

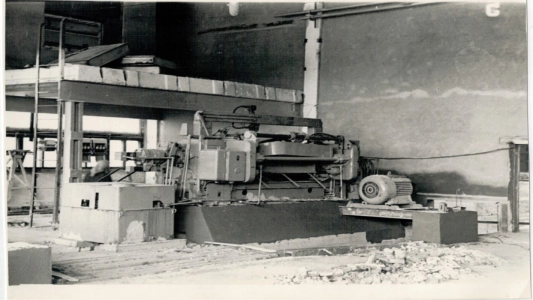

In 1972 a plywood workshop was put into operation, producing construction plywood of the PC brand (plywood + carbamide glue), veneer, furniture, elastic elements. At first, the workshop under construction grew into a separate division, which later played an important role in the life of the plant.

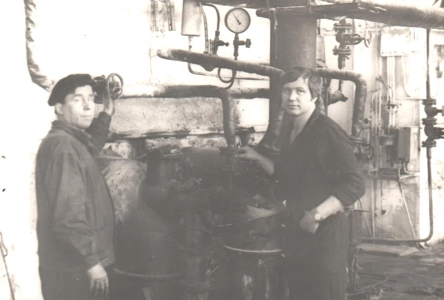

In the same year, an antipyreation and antisepting workshop was built, in which the lumber was treated with means that prevent it from burning and rotting.

In 1992, the enterprise was transformed into a closed Joint-Stock company "Zavolzhsky Woodworking Plant No. 3" (Closed Joint-Stock Company "ZDOZ No. 3"): production is being modernized, a checkpoint is being organized, part of the workshops is being redesigned. It should be noted that in the Soviet years, the main specialization of the enterprise was the production of joinery for the construction of Social and Cultural buildings. Since the early 90s, schools, hospitals, kindergartens and other public buildings have practically ceased to be built. The distribution of orders from the center has stopped. As well as the central financing stopped. Therefore, the Zavolzhsky DOZ faced the need to reorganize production and search for new markets for its products. Maybe it is this ability to survive in the most difficult conditions that helps the company's staff to this day.

The main two product lines at that time were the assembly of residential buildings with wooden windows and the production of plywood. The company has focused its resources on the development of these areas. The area of supply of the company's products has spread from Belgorod to Vladivostok.

Individual wooden windows manufactured by Zavolzhsky DOZ have been repeatedly celebrated at exhibitions in Moscow, Nizhny Novgorod and Kazan.

Having analyzed the current trends in woodworking, the company enters the market of wooden house construction. I must say that ZAVDOZ had previously made attempts to develop sets of panel houses, but at that time the garden houses had no commercial prospects and served rather to meet the demand of local residents. Now, having extensive experience in installing Euro windows in wooden cottages, communicating with customers, analyzing the pros and cons of all technologies, the one for which the future of wooden construction and low–rise construction in general is glulam was consciously chosen. The choice was influenced by the quality of technology, the ability to control the construction of a turnkey house, and the durability of the structure. Raw materials (cylindrical and profiled massive timber) were rejected immediately due to the inability to control the process of commissioning the house. The situation when a house is being built and then left "for shrinkage" did not suit, since in such conditions it is impossible to organize full-fledged quality control. Namely, it, together with preserving the reputation of the enterprise in the long term, was and remains to this day the most important task of the enterprise.

A house-building workshop is being launched. At first, the workshop works only within the Nizhny Novgorod region, developing construction technology. All the first houses must be pre-assembled at the enterprise, all the complex aspects of the technology of building houses from glulam are collected and analyzed.

In the same year the drying facility was completely re–equipped - automatic drying chambers manufactured by KATRES (Czech Republic) were put into operation.

In 2011-2012 the house—building workshop was restarted. The original experimental equipment has been completely replaced with automatic imported production lines. The capacity of the new workshop amounted to 600 m3 per month. This is about 5-15 house kits of various sizes. The ceremonial launch of the opening of the new workshop on February 21, 2012 was made by the Minister of Construction of the Nizhny Novgorod region Chelomin Vladimir Nikolaevich.

The equipment used is imported, at the time of launch, the most modern in the world. The new modern workshop made it possible to produce glulam up to 310 mm thick and up to 360 mm high, which meets the requirements of all climatic zones. The automatic German optimizer, built into the standard technology of housing construction, allows you to produce a twigless Premium timber. And the accumulated experience of woodworking allows you to produce glulam from any kind of wood, including combining them in one product. The main equipment of this workshop was the Krusi CMI-4×4 automatic cup cutting machine (Switzerland).

At the end of 2016 another production division of the group is being organized. The total production capacity of house kits amounted to more than 1200 m3 per month. Some of the products were supplied to partners abroad in the Czech Republic, Germany, and Cyprus.

ZAVDOZ is building a temple in honor of the Blessed Life-Giving Trinity in the village of Barmino in the Lyskovsky district of the Nizhny Novgorod region.

Houses made of glulam ZAVDOZ began to be supplied to other countries — Serbia, Latvia, South Korea, Kazakhstan, the Republic of Belarus, Germany, Turkey.

The third line of housing construction has been launched. The production is equipped with a 5-coordinate machine with universal tooling Hundegger (Germany), which allows you to perform the most complex wooden joints with high production speed and high precision of cutting parts.

The new line allows you to produce houses using the "real half-timbered" technology that has become popular

At the same time, ZAVDOZ, with the support of the regional Export Development Center, continues to increase its export potential, actively looking for new markets and buyers of its products outside the Russian Federation. The plant's management actively participates in business missions (Egypt, Turkey, Armenia and Kazakhstan), finding long-term business partners and customers there.